The Importance of Viewing Data to Resolve Motorcycle Issues

Fault Codes May Not Provide the Full Picture

If you are only looking for fault codes, you may miss a lot of problems!

A Real-World Example

In this case, a system was purchased by an individual to work on both his own and a friend's motorcycle. The friend's motorcycle has had an issue for some time which has not been resolved after being taken to several mechanics. Despite being sold some new parts, the issue remained.

So, between them, they purchased a Texa system to work on their own motorcycles and hopefully get to the bottom of this particular issue. After a short conversation with the user, they told us they figured the issue was possibly due to faulty temperature sensors/s, so had a replacement on order.

This was a deduction made because they had 2 almost identical bikes and had compared temperature data between bikes from the air intake sensor mounted on the airbox. The one on the "faulty" bike read around 15 degrees higher than the "non faulty" bike. So, this would be a fair assumption, however, we were not convinced that this would be the entire cause of the severe symptoms previously described to us.

Discovering the Real Issue

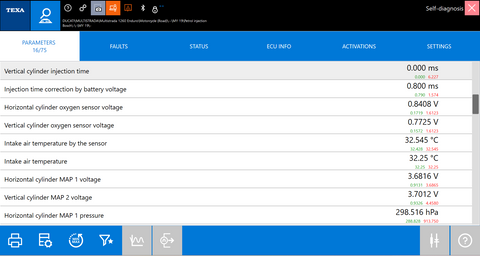

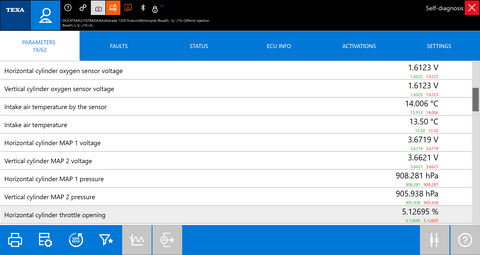

We were then emailed 3 screen shots, one of which immediately flagged the main issue. The MAP sensor value was shown as 298.5 hPa (1hPa = 1 mbar). The engine was not running so this should have been displaying barometric pressure. Roughly 1000 hPa at sea level (1000 mbar). The client was at around 3000ft above sea level so we should have seen around 900Hpa - which we did on the 2nd bike, by pure chance we have that data shown in a screen shot also below.

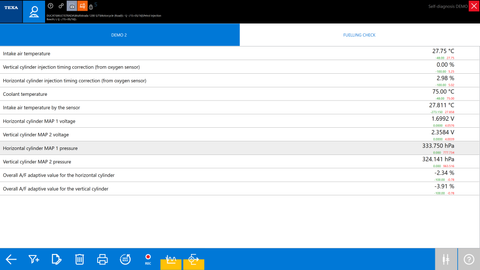

There is other data we would like to see, but this is what we have been provided so far. Below is a demo example of a filtered list of relevant information we would like to see next time.

The filter option is a great way to only see data relevant to your issue. This bike has over 60 potential data streams so we really need to drill down on specific information relating to the symptoms we have. In this demo, we are viewing simulated data with the engine running, so we expect the MAP values to be lower than atmospheric pressure.

Why Data is Important

So this is a great example of why using the available data is important to resolve faults. The temperature sensor and the MAP sensor are both working, but not correctly. They are not completely broken, they do not have a short or open circuit, therefore you will not be shown an error code to indicate this fault. Only the data can help you. Now replacing these components may be the end of it, however we always recommend checking and testing all related wiring and connectors to be sure there are no other issues with high resistance and volt drop before making final conclusions and spending money on parts.

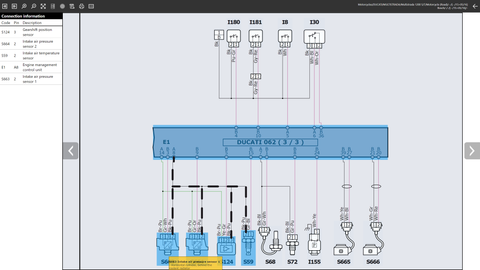

As it happens, the temperature sensor is on the same ecu ground circuit as the MAP sensors.... So we really want to check both MAP sensors, AND test grounds for high resistance/volt drop and clean up any connectors that may be part of the problem.

End Result

A couple of weeks later we contacted the client to see if they had received and fitted the parts. They had, and the bike was now running as it should. The client was very happy and knew he would be able to deal with most issues from now on as well as completing their own service resets.

Conclusion

No matter what diagnostic system you have, the user needs to understand the data presented to them. Relying on fault codes can give you a start on diagnosing the problem, but that only works if you have a fault code! If you have no DTC's displayed, you have no choice but to look at data to work out which values are incorrect, then together with the symptoms you can usually narrow down the issue fairly quickly.

Texa Diagnostic Software offers a wide range of other features that can help you diagnose and repair problems more efficiently. These include the ability to read and clear fault codes, reset service reminders, view live sensor values, control unit information, log and graph live values, and more.

Remember to subscribe to our youtube channel here

and we also have a facebook page here where updates and news are posted weekly.